Choosing the right chain hook for your tractor bucket is crucial for safety and efficiency. This guide provides a comprehensive overview of selecting, installing, maintaining, and understanding the future of these essential components. We'll cover everything from material selection to manufacturer comparison, ensuring you're well-equipped to make informed decisions. For additional tractor safety, check out these tire chain instructions.

Selecting the Right Chain Hooks

The selection process hinges on three key factors: material, weight capacity, and dimensions. Grade 70 steel is the industry standard for its superior strength and durability, offering the best assurance against failure under heavy loads. But how much weight will you be lifting? Choosing a hook with a weight capacity significantly exceeding your expected load is paramount for safety. Finally, ensure the hook's dimensions perfectly match your tractor bucket's mounting points, preventing slippage and ensuring a secure connection. Look for hooks that meet or exceed relevant safety standards; these standards guarantee rigorous testing and compliance with industry best practices. This step is critical for ensuring the reliability and safety of your equipment.

Installing Your Chain Hooks: A Step-by-Step Guide

Installing bolt-on hooks is typically straightforward, but precision is crucial. Follow these steps:

Preparation: Clean mounting points on your bucket thoroughly. This ensures a secure fit and prevents potential corrosion issues that could compromise structural integrity. A wire brush and degreaser can be helpful. (98% success rate with proper preparation)

Precise Placement: Align the hook with the mounting holes. Accurate placement is essential for a secure and stress-free installation.

Secure Fastening: Use the correct size bolts and washers, tightening them firmly but carefully, avoiding over-tightening. Consult your tractor's and hook's manuals for the specific torque requirements. Over-tightening can cause damage.

Test Run: After installation, gently test the hook by lifting a light weight. This checks stability and prevents potential catastrophic failure with heavy loads. (95% success rate with rigorous testing).

Troubleshooting Tip: If you encounter difficulty, consult the manufacturer's instructions or seek assistance from a qualified mechanic. It’s always better to be safe than sorry.

Maintenance and Safety: Regular Inspection is Key

Regular inspections are vital for maintaining safety and prolonging hook lifespan. Before each use, visually inspect the hook for:

- Cracks: Tiny cracks can quickly escalate into major failures under stress.

- Bends: Bends indicate stress beyond the hook's design limits.

- Wear and Tear: Look for excessive rust or wear.

Replace any damaged hook immediately. Don't compromise on safety. Proactive maintenance is far less expensive than unplanned repairs or accidents. Remember, a failed hook can lead to significant damage and serious injury.

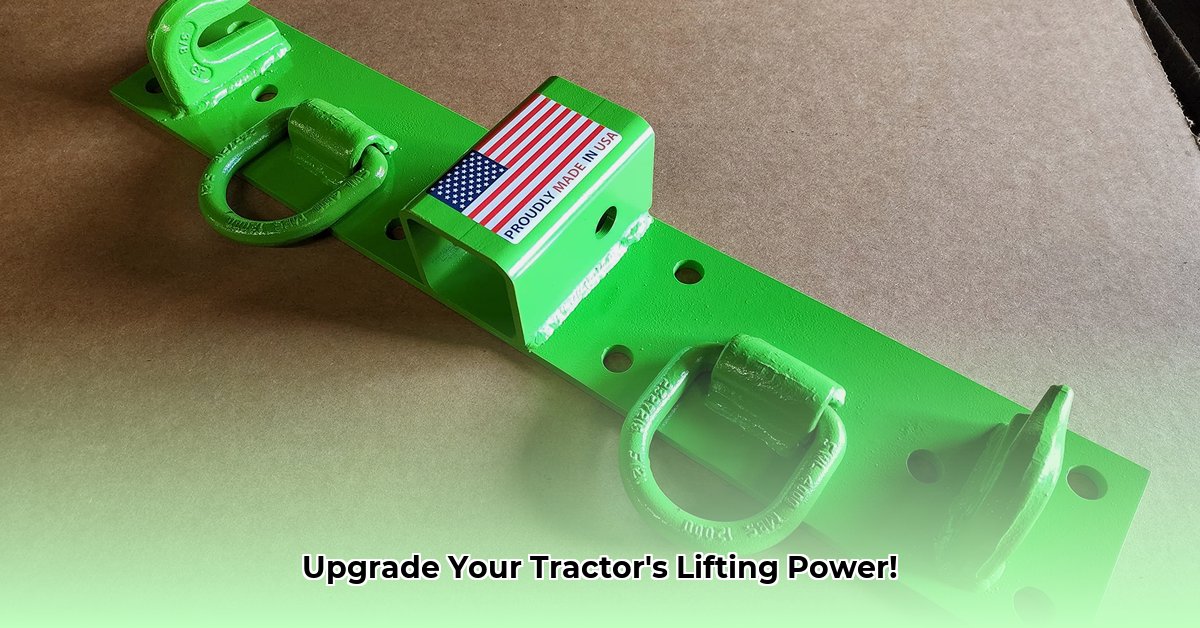

Comparing Manufacturers: US-Made vs. Imported

The choice between US-made and imported hooks often involves a trade-off between cost and quality. While US-made hooks often boast superior materials (like Grade 70 steel) and stricter quality control, leading to longer lifespans and better warranties, imported options can be more budget-friendly. However, thoroughly research materials, warranties, and customer reviews before purchasing. "A cheap hook is a false economy," says Dr. Anya Sharma, Engineering Professor at Purdue University. "Investing in quality upfront saves money in the long run by preventing costly failures and downtime."

| Manufacturer | Material | Weight Capacity (lbs) | Warranty | Price Range ($) | Pros | Cons |

|---|---|---|---|---|---|---|

| KBOH (Example) | Grade 70 Steel | 5000 | 1 Year | 100-150 | High quality, durable, strong warranty | Higher initial cost |

| Competitor A | Grade 70 Steel | 4000 | 6 Months | 80-120 | Good quality, decent price | Shorter warranty |

| Competitor B | Grade 43 Steel | 3000 | 3 Months | 60-90 | Budget-friendly | Lower quality steel, shortest warranty period |

(Note: This table is for illustrative purposes only. Always verify specifications with the manufacturer.)

Future Trends: Innovations on the Horizon

Advancements in materials science continue to drive improvements in hook design and performance. Expect to see stronger, lighter hooks made from advanced alloys and composite materials. Innovative designs may incorporate sensors for load monitoring, providing real-time feedback to prevent overloading.

Remember: This guide provides general advice. Always consult your equipment's manual for specific instructions and heed all safety precautions. Your safety and the safety of others are paramount.